Key features and uses of aluminum pipe elbows

2023-10-18

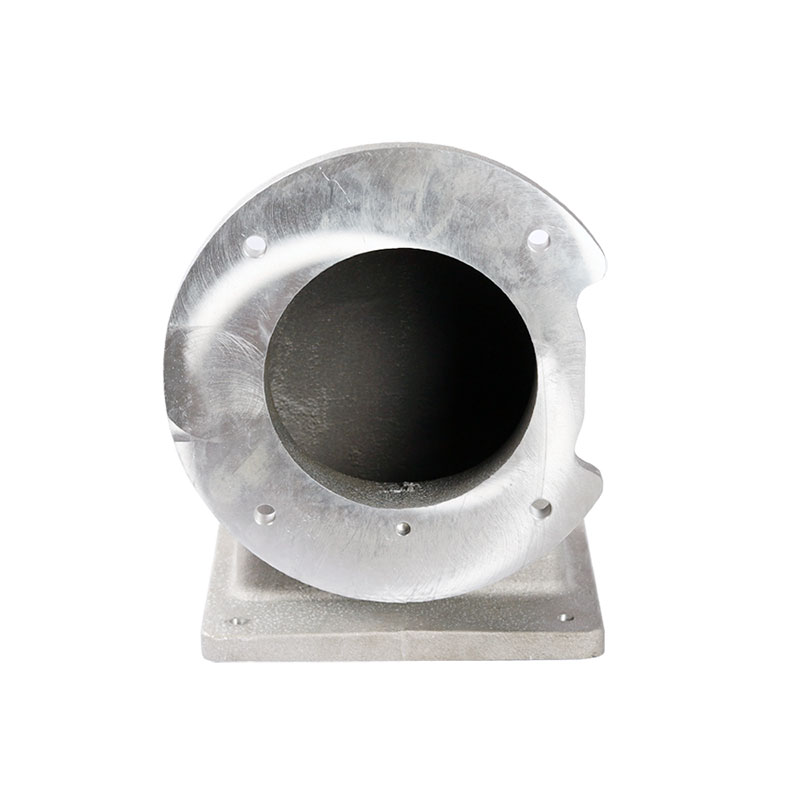

Aluminum pipe elbows are pipe fittings designed to change the direction of an aluminum pipe or tubing system. They are commonly used in various industrial, construction, and plumbing applications where lightweight and corrosion-resistant piping is required. Aluminum pipe elbows are known for their durability, resistance to corrosion, and relatively low weight compared to other metal pipe materials. Here are some key features and uses of aluminum pipe elbows:

1. Material: Aluminum pipe elbows are typically made from various grades of aluminum, including 6061-T6 and 6063-T6. These alloys offer a combination of strength, corrosion resistance, and workability.

2. Shapes and Angles: Aluminum pipe elbows come in various shapes and angles to suit different applications. Common angles include 45 degrees and 90 degrees, but custom angles are also available.

3. Size: The size of the aluminum pipe elbow should match the diameter of the aluminum pipe it connects. These fittings are available in a range of sizes, typically measured in inches or millimeters.

4. End Connections: Aluminum pipe elbows may have different end connections, including threaded, flanged, or welded ends, depending on the specific requirements of the piping system.

5. Weldability: Aluminum pipe elbows can be easily welded to aluminum pipes or tubing using TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding processes, ensuring a secure and leak-free connection.

Uses of Aluminum Pipe Elbows:

1. Piping Systems: Aluminum pipe elbows are commonly used in various piping systems, such as air handling, water distribution, and fluid transport, particularly in industries where corrosion resistance is critical.

2. HVAC (Heating, Ventilation, and Air Conditioning): They are used in HVAC systems to change the direction of airflow, connect ventilation ducts, and create customized configurations for ductwork.

3. Automotive and Aerospace: Aluminum pipe elbows find applications in the automotive and aerospace industries for exhaust systems, intercooler piping, and fluid transfer.

4. Construction: In construction projects, aluminum pipe elbows are used for handrails, balustrades, and architectural elements due to their lightweight and corrosion-resistant properties.

5. Industrial Machinery: They are utilized in industrial machinery for conveying fluids, gases, and coolants.

6. Marine: Aluminum pipe elbows are favored in marine applications due to their resistance to saltwater corrosion and lightweight nature.

7. Food and Beverage Industry: In the food and beverage industry, aluminum pipe elbows are used for conveying liquids and maintaining hygiene standards.

Aluminum pipe elbows offer numerous advantages, including their lightweight construction, corrosion resistance, and ease of installation. When using aluminum pipe elbows, it's essential to ensure proper alignment and sealing to prevent leaks in the piping system. Additionally, welding should be performed according to industry standards and safety guidelines to maintain the integrity of the joint.