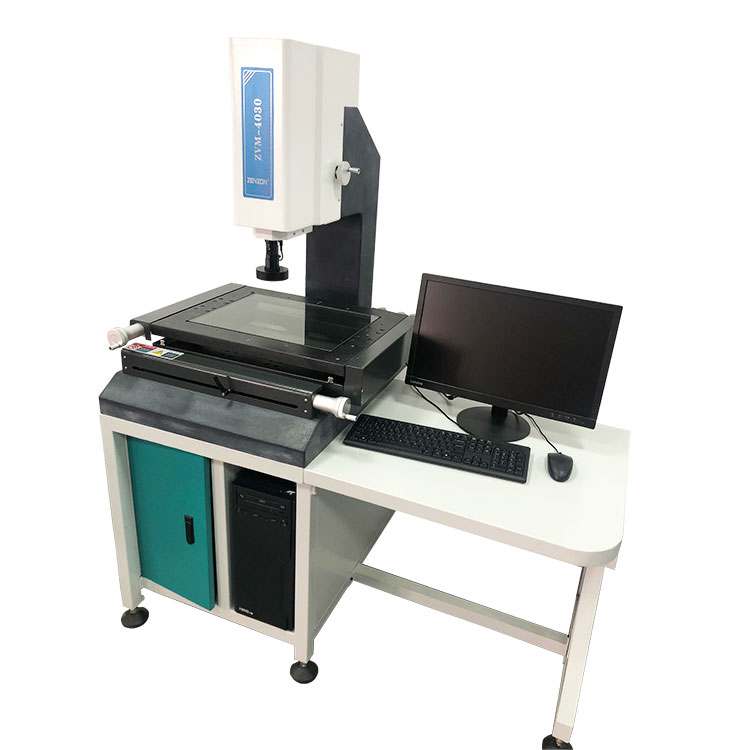

What are the maintenance for this Manual Video Measuring Machine

2023-10-26

Maintaining a Manual Video Measuring Machine (VMM) is crucial to ensure its long-term accuracy and reliable performance. Proper maintenance helps prevent wear and tear, extends the machine's lifespan, and minimizes the risk of measurement errors. Here are some key maintenance tasks for a Manual VMM:

1. Regular Cleaning: Keep the machine clean and free from dust and debris. Use a soft brush or compressed air to remove loose particles from the machine's components, including the camera lens, lighting system, and measurement stage.

2. Cleaning the Camera Lens: The camera lens can accumulate dust and smudges over time, affecting image quality. Clean the lens using a soft, lint-free cloth and a mild optical lens cleaning solution as needed. Avoid abrasive materials that could scratch the lens.

3. Cleaning the Lighting System: Ensure that the lighting system is free from dirt and dust. Clean the LED or fiber-optic lights to maintain consistent and even illumination on the object being measured.

4. Calibration: Regularly calibrate the VMM according to the manufacturer's recommendations. Calibration should be performed using known standards or calibration artifacts to maintain measurement accuracy.

5. Lubrication: Some VMMs may have moving parts that require periodic lubrication. Follow the manufacturer's guidelines for lubrication, and use recommended lubricants.

6. Inspecting Fixtures: If you use fixtures or clamping mechanisms to hold objects during measurement, inspect them for wear, damage, or contamination. Proper fixturing is essential to ensure accurate measurements.

7. Environmental Control: Maintain stable environmental conditions in the measurement area. Ensure that temperature and humidity levels are within the recommended range. Avoid strong vibrations and fluctuations that can impact measurement accuracy.

8. Software Updates: Keep the measurement software up to date by installing software updates and patches provided by the manufacturer. Updated software often includes bug fixes and performance enhancements.

9. Operator Training: Ensure that operators are well-trained in the proper use of the VMM and measurement software. Proficient operators are less likely to make errors that can affect the machine or measurements.

10. Record Keeping: Maintain records of calibration dates, maintenance activities, and any issues or repairs. These records can help track the machine's performance and identify trends over time.

By performing these maintenance tasks regularly and proactively addressing any issues or concerns, you can keep your Manual Video Measuring Machine in optimal working condition and ensure that it continues to deliver accurate and reliable measurements.