Unraveling the Pricing Puzzle: Factors Influencing Petroleum Resin Prices

2024-03-18

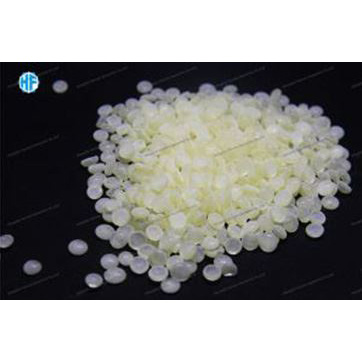

In the world of industrial materials, pricing dynamics play a critical role in shaping market trends, supply chains, and profitability. Petroleum resin, a versatile synthetic resin derived from petroleum feedstocks, is no exception. Understanding the factors that influence petroleum resin prices is essential for manufacturers, suppliers, and consumers alike. In this blog, we'll delve into the intricate web of factors that impact the pricing of petroleum resin in the market, shedding light on the forces driving fluctuations and trends.

Raw Material Costs:

1. Crude Oil Prices:

As petroleum resin is derived from petroleum feedstocks, fluctuations in crude oil prices directly influence its production costs. Changes in global oil supply and demand dynamics, geopolitical tensions, and OPEC (Organization of the Petroleum Exporting Countries) decisions can cause volatility in crude oil prices, thereby affecting petroleum resin pricing.

2. Naphtha Prices:

Naphtha, a primary feedstock for petroleum resin production, accounts for a significant portion of manufacturing costs. Variations in naphtha prices, driven by factors such as refinery capacity, feedstock availability, and petrochemical demand, impact the cost structure of petroleum resin production.

Supply and Demand Dynamics:

1. Market Demand:

Fluctuations in market demand for petroleum resin across industries and regions influence pricing trends. Strong demand from sectors such as adhesives, coatings, printing inks, and rubber compounding can exert upward pressure on prices, especially during periods of robust economic growth and industrial activity.

2. Supply Chain Disruptions:

Disruptions in the supply chain, such as production outages, transportation constraints, or logistical challenges, can lead to supply shortages and price spikes. Natural disasters, geopolitical conflicts, and regulatory changes may disrupt the flow of raw materials and finished products, impacting petroleum resin availability and pricing.

Production Costs and Capacity:

1. Operating Costs:

Factors such as energy costs, labor expenses, and regulatory compliance requirements contribute to the overall production costs of petroleum resin manufacturers. Rising operating costs may necessitate price adjustments to maintain profitability, particularly in periods of economic uncertainty or inflationary pressures.

2. Production Capacity:

The availability of production capacity and industry consolidation within the petroleum resin sector influence pricing dynamics. Tight supply-demand balances, limited production capacity, or capacity expansions can affect pricing trends, with tight market conditions often leading to higher prices.

Market Competition and Pricing Strategies:

1. Competitive Landscape:

Competition among petroleum resin manufacturers, both domestic and international, influences pricing strategies and market dynamics. Pricing pressures may arise from competitive pricing, product differentiation, and market share considerations, driving manufacturers to adjust prices to maintain competitiveness.

2. Contractual Agreements:

Long-term supply contracts, pricing agreements, and negotiations between suppliers and customers play a significant role in determining petroleum resin prices. Price escalation clauses, volume discounts, and supply chain partnerships may mitigate price volatility and provide pricing stability for both parties.

Regulatory Factors:

1. Environmental Regulations:

Regulatory compliance costs, emissions standards, and sustainability initiatives impact production processes and cost structures in the petroleum resin industry. Stringent environmental regulations may require investments in pollution control technologies or renewable energy sources, potentially affecting pricing.

2. Trade Policies and Tariffs:

Trade policies, tariffs, and trade disputes between countries can influence the cost of imported petroleum resin and disrupt global supply chains. Tariffs on raw materials, intermediate products, or finished goods may result in higher costs for petroleum resin manufacturers and end-users.

Conclusion:

The pricing of petroleum resin in the market is influenced by a complex interplay of factors, including raw material costs, supply and demand dynamics, production capacity, market competition, regulatory requirements, and geopolitical developments. Manufacturers, suppliers, and consumers must closely monitor these factors and adapt to changing market conditions to mitigate risks, optimize pricing strategies, and ensure competitiveness in the dynamic landscape of the petroleum resin market. By understanding the underlying forces driving pricing fluctuations, stakeholders can make informed decisions and navigate market challenges effectively in pursuit of sustainable growth and profitability.