The manufacturing process for bronze bonded grinding wheels

2023-11-04

The manufacturing process for bronze bonded grinding wheels is a precise and carefully controlled procedure. It involves several steps to create a grinding wheel that meets the desired specifications for a particular application. Here's an overview of the manufacturing process:

1. Material Selection: The process begins with the selection of high-quality materials. This includes choosing the appropriate abrasive material (e.g., aluminum oxide, silicon carbide, diamond, or CBN) and the bronze matrix material. The type and quality of these materials are crucial for the grinding wheel's performance.

2. Mixing: The selected abrasive material and bronze matrix material are mixed together in the correct proportions. The mixing process ensures a homogenous blend of these materials.

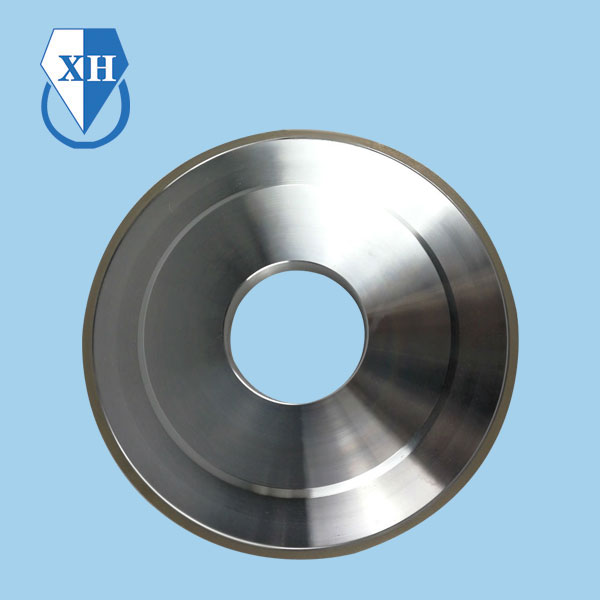

3. Molding: The mixed materials are then placed into a mold that has the desired shape and dimensions of the grinding wheel. Molds can have various shapes, including flat wheels, cylindrical wheels, cup wheels, and more.

4. Compaction: Pressure is applied to the mixture within the mold to compact the materials. This compaction process helps create a dense and solid structure within the mold, ensuring uniform distribution of abrasive particles.

5. Sintering: The mold, containing the compacted mixture, is subjected to high temperatures in a sintering furnace. During sintering, the bronze matrix material melts and fuses with the abrasive grains. As the mixture cools, the bronze solidifies and forms a strong bond with the abrasive material. The sintering process is critical for creating a well-bonded grinding wheel.

6. Cooling: After sintering, the grinding wheel is allowed to cool. This cooling process is essential for stabilizing the wheel's structure.

7. Shaping and Sizing: The grinding wheel may undergo additional shaping and sizing processes to achieve the desired dimensions, including diameter, thickness, and wheel structure. These processes can include trimming, cutting, or grinding the wheel to its final shape.

8. Dressing and Profiling: The wheel may be dressed and profiled to ensure that it has the required shape and sharpness before use. Dressing may involve the removal of any excess material, reshaping, or truing to maintain the wheel's accuracy.

9. Quality Control: Throughout the manufacturing process, quality control measures are employed to ensure that the grinding wheel meets the required specifications. This includes checking the dimensions, hardness, balance, and other performance characteristics.

10. Packaging: Once the grinding wheel passes quality control, it is packaged and prepared for distribution to end-users. Proper packaging is essential to protect the wheel from damage during transportation and storage.

The specific manufacturing process may vary based on factors such as the type of abrasive material used, the desired wheel structure, and the intended application. The quality of materials and the precision of each manufacturing step are critical in producing high-quality bronze bonded grinding wheels that offer consistent performance and durability.