Everything You Need to Know About Printing Waterproof Label Stickers

2024-11-28

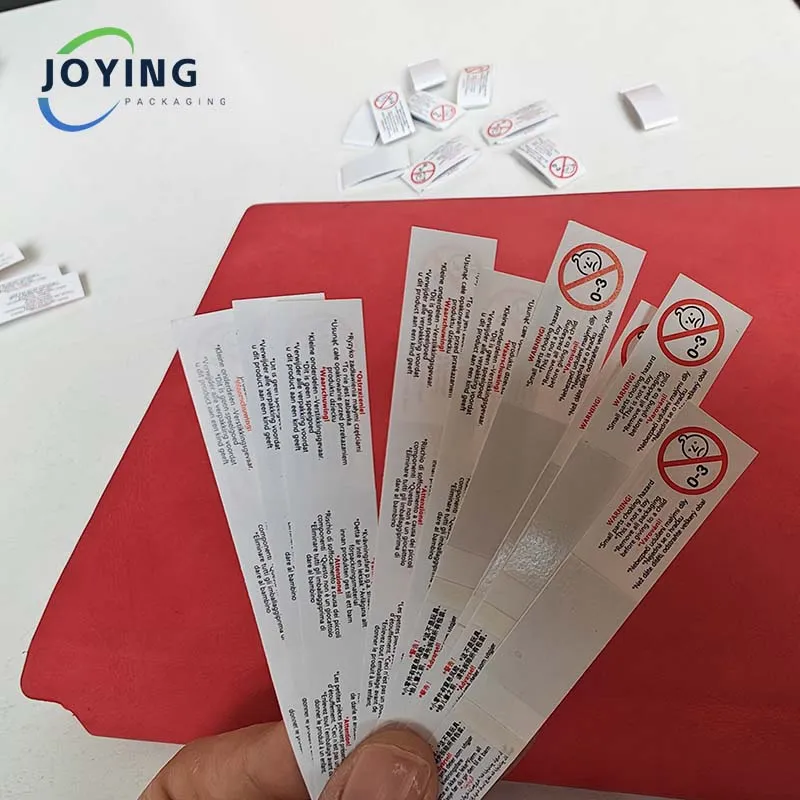

In the world of labeling, durability and functionality are key. Whether it's for products exposed to moisture, outdoor environments, or harsh conditions, waterproof label stickers are an essential solution. These labels are designed to withstand the elements and remain intact even in wet, humid, or submerged conditions. In this blog, we’ll explore the benefits, features, and applications of printing waterproof label stickers, along with the technologies that ensure their reliability.

What Are Waterproof Label Stickers?

Waterproof label stickers are designed to be resistant to water, moisture, and humidity. They are made from materials that do not absorb water or degrade when exposed to wet environments, making them ideal for a variety of applications. These labels are printed with special inks and materials that prevent smudging or fading when exposed to rain, water, or condensation.

Unlike regular paper labels that may dissolve, peel, or fade when wet, waterproof labels retain their readability and adhesion even in challenging conditions. These qualities make waterproof label stickers a must-have for industries where products are exposed to moisture, outdoor conditions, or need to withstand refrigeration or freezing temperatures.

Key Features of Waterproof Label Stickers

1. Water Resistance:

The main feature of waterproof labels is their ability to resist water. Made from synthetic materials like polyester, vinyl, or BOPP (biaxially oriented polypropylene), these materials are water-repellent, preventing water from damaging or soaking through the label. Waterproof labels are crucial for products that will be exposed to moisture or direct contact with water.

2. Durability and Longevity:

Waterproof labels are designed to last longer than regular paper labels. The materials used are often more durable, tear-resistant, and can withstand abrasion, scratches, and UV exposure. This makes them ideal for both indoor and outdoor applications, where labels need to stay intact and legible for extended periods.

3. Fade Resistance:

Printing waterproof label stickers requires specialized inks that resist fading, even when exposed to sunlight, UV rays, or environmental pollutants. This ensures that the printed text, logos, and barcodes remain visible throughout the product's lifespan, regardless of exposure to the elements.

4. Adhesive Strength:

The adhesive used in waterproof label stickers is typically strong enough to stick to a wide variety of surfaces, including plastic, glass, metal, and even corrugated boxes. The adhesive is designed to bond firmly to surfaces without peeling off due to water exposure.

5. Customizability:

Waterproof labels can be customized in terms of size, shape, design, and color. Whether you need a simple barcode label or a full-color logo design, waterproof stickers can be printed to suit your exact specifications. This customization allows for branding and marketing consistency across product lines.

Technologies Used in Printing Waterproof Label Stickers

To achieve the water-resistant properties of these labels, manufacturers use several printing technologies:

1. UV Printing:

UV printing uses ultraviolet light to cure ink as it is printed. The process results in a durable, smudge-proof print that is ideal for labels exposed to harsh conditions. UV printing helps waterproof labels retain their sharpness, vibrancy, and legibility even after exposure to water, sunlight, or chemicals.

2. Thermal Transfer Printing:

Thermal transfer printing involves using a heated printhead to transfer ink or ribbons onto the label material. This method creates highly durable prints that are resistant to fading, scratching, and water exposure. It is commonly used for printing barcodes and labels that need to remain legible under harsh conditions.

3. Flexographic Printing:

Flexographic printing is a widely used method for printing waterproof labels, especially for large-scale production. The process involves flexible printing plates that apply ink to the label material. This method is cost-effective for printing large batches of waterproof labels and is commonly used for product packaging and branding.

4. Digital Printing:

Digital printing allows for high-quality, full-color prints with quick turnaround times. This method is ideal for short runs or customized designs on waterproof labels. Digital printing can also support variable data, such as QR codes or serial numbers, which is useful for product tracking and inventory management.

Applications of Waterproof Label Stickers

1. Outdoor Products and Equipment:

Waterproof labels are perfect for products used in outdoor environments, including gardening tools, camping gear, outdoor electronics, and automotive products. These labels ensure that logos, instructions, and product details remain visible, even after exposure to rain, dirt, or extreme weather conditions.

2. Food and Beverage Packaging:

In the food and beverage industry, waterproof labels are essential for products that may be refrigerated, frozen, or exposed to condensation. These labels are often used for bottled beverages, frozen food packaging, and even perishable goods that require clear and durable labeling.

3. Industrial Applications:

Waterproof labels are also widely used in industrial environments where equipment and tools are exposed to moisture, chemicals, and dirt. They are used for labeling pipes, containers, machinery, and safety signs to ensure that critical information stays intact and readable under tough conditions.

4. Pharmaceutical and Healthcare Products:

In the pharmaceutical industry, waterproof labels are necessary for medicine bottles, tubes, and medical equipment. Labels need to withstand conditions such as humidity and exposure to water, ensuring that vital information like dosage instructions, expiration dates, and warnings remain intact.

5. Logistics and Shipping:

Waterproof labels are also commonly used in logistics and shipping. These labels are designed to withstand exposure to water, dirt, and rough handling during transportation, ensuring that shipping information and barcodes remain scannable and readable.

Waterproof label stickers offer a range of benefits, from water resistance and durability to fade-proof performance and strong adhesive properties. Whether you’re in manufacturing, retail, logistics, or food and beverage industries, waterproof labels are crucial for ensuring that your products remain properly identified and labeled, even in wet or harsh environments. With advancements in printing technology, companies can produce high-quality waterproof labels that meet their specific needs for durability, legibility, and aesthetics.

Investing in waterproof label stickers not only ensures that your product packaging looks professional and holds up in various conditions, but it also helps to build brand reputation by providing customers with reliable, high-quality products.